MIL-C-21067C (MI)

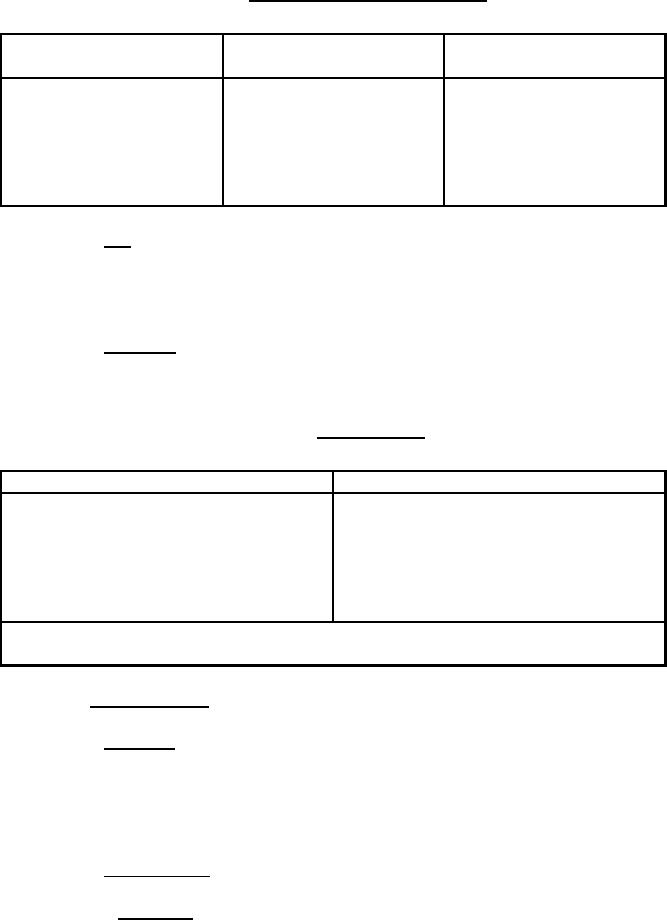

TABLE I. Quality conformance inspection.

INSPECTION

REQUIREMENT

TEST PARAGRAPH

PARAGRAPH

Viscosity

3.3.1

4.6.1

Solids

3.3.2

4.6.2

Tensile strength

3.3.3

4.6.3

Ultimate elongation

3.3.4

4.6.3

Adhesion, initial

3.3.5

4.6.4.2

Color

3.8

4.6.4.5

4.5.1 Lot. A lot shall consist of all the material submitted for acceptance at the

same time, which has been produced by one manufacturer in one continuous operation

without change in materials or processes, but shall consist of a quantity not greater

than 2500 lbs.

4.5.2 Sampling. Sampling to verify conformance to section 3 requirements

shall be performed in accordance with table II. Each container in a lot shall be

considered as a unit of product.

TABLE II. Sampling plan.

LOT SIZE

SAMPLE SIZE

1 to 13

100 %

14 to 150

13

151 to 280

20

281 to 500

29

501 to 1200

34

1201 to 3200

42

* In all cases: Acceptance number is ZERO

Rejection number is One

4.6 Test procedures.

4.6.1 Viscosity. Viscosity of the coating compound shall be determined with

either a Brookfield or a McMichael viscosimeter, or equivalent. The test shall be run

in duplicate using a new sample of material for each determination. Both the sample

of coating compound and the apparatus shall be conditioned at the testing temperature

of 27º ± 5ºC for 4 hours before testing (see 3.3.1).

4.6.2 Solids content.

4.6.2.1 Procedure. A covered low-form weighing bottle shall be weighed, and

approximately 10 grams of thoroughly mixed coating compound shall be poured into

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business