MIL-DTL-450D

(3) Fill a cylindrical container, at least 3 inches in diameter, with the sample to a depth

of at least 3 inches.

(4) Bring the sample to 77 ± 1 ºF and level the exposed surface.

(5) Level the penetrometer.

(6) Place the container on the penetrometer table so that the approximate center of the

exposed surface lies beneath the tip of the cone.

(7) Adjust the height of the penetrometer table and plunger assembly until the tip of the

cone just touches the surface of the sample.

(8) Release the plunger assembly and allow to remain free for 5 seconds.

(9) Read the penetrometer [depth of penetration expressed in tenths of millimeter (mm)].

(10) Raise the plunger assembly, level the exposed surface of the sample, and repeat the

test as directed above.

(11) Report the average of 10 tests if the mean deviation of the first five values exceeds 3

percent.

4.4.10 Drying time.

4.4.10.1 Equipment.

a. Film applicator (see Table IV).

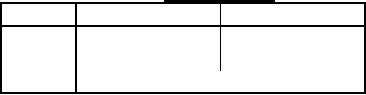

Table IV. Film applicator.

Film applicator (in) Gap clearance (in)

Type

0.0030

0.0060

I

0.0020

0.0040

II

To produce a 0.015 inch wet film thickness

III

4.4.10.2 Methods.

a. Method 1 (Dust-free). Determine dust-free time in accordance with method 4061.3 of

FED-STD-141 using the film applicator specified in Table IV. Observe for compliance with

Table II.

b. Method 2 (Free from after-tack). Determine free from after-tack time in accordance

with method 4061.3 of FED-STD-141 using the film applicator specified in Table IV. Observe

for compliance with Table II.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business