MIL-PRF-62218B

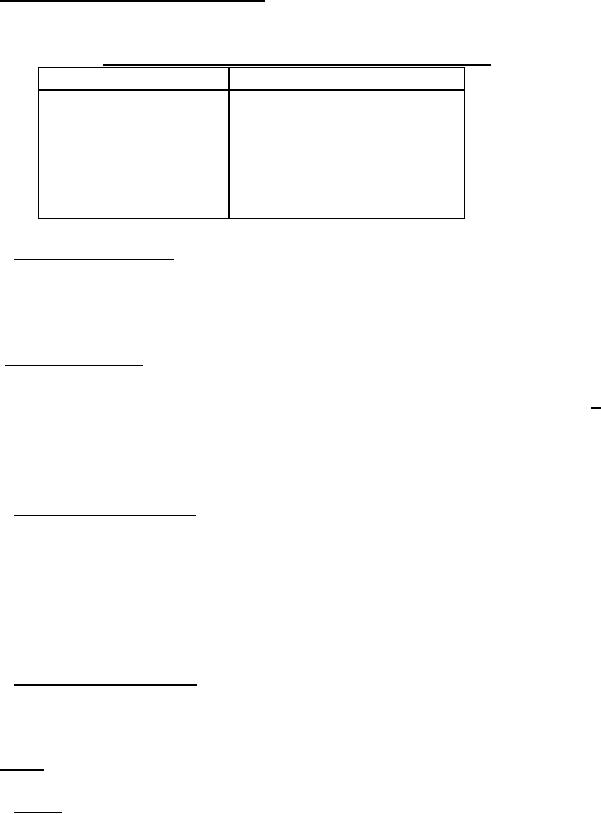

4.6.5 Chemical and physical characteristics. To determine conformance to 3.3.1 through

3.3.4, the compound shall be tested in accordance with the methods specified in table III.

TABLE III. Test methods for chemical and physical characteristics.

Characteristic

Method

Nonvolatile content

FED-STD-791, method 3480

Weight per gallon

ASTM D1475

Sulfated ash content

ASTM D874

Water content

ASTM D95

Lead content

ASTM D3335

Flash point

ASTM D93

4.6.5.1 Condition in container. To determine conformance to 3.3.5, the compound shall

be observed in the container in which the material was submitted for test and prior to any

agitation. The presence of lumps or skins shall be noted and a spatula or paddle shall be lowered

into the container to establish evidence of settling or separation of the solvent.

4.6.6 Film characteristics. To determine conformance to 3.4.1, three test panels shall be

prepared as specified in 4.6.6.1 and coated as specified in 4.6.6.2. The wet film shall be examined

for evidence of sag. The test panels shall be permitted to air-dry in a vertical position for 7 days +

2 hours at a temperature of 25 ± 3°C (77 ± 5°F). To determine if the costing is continuous, the

dry test panels shall be examined under 10X magnification. An Elcometer gage or an equivalent

gage shall be used to determine the dry film thickness of the coating.

4.6.6.1 Preparation of test panels. Test panels shall be prepared from cold rolled steel,

commercial quality, conforming to type 2 of ASTM D609. The test panels shall be approximately

102 by 305 mm (4 by 12 in) of any convenient size thickness greater than

0.64 mm (0.025

in). The edges shall be well rounded. The test panels shall be cleaned in accordance with Method

D of ASTM D609. After cleaning, the test panels shall be stored in a desiccator and shall be

used the same day they are prepared. The test panels shall be handled with forceps or other

instruments at all times to avoid fingerprint corrosion.

4.6.6.2 Application of compound. The test panel shall be held in a vertical position and

the compound shall be sprayed on the test panel in a single back and forth motion to the

manufacturer's designated wet film thickness.

4.6.7 Creep.

4.6.7.1 Type I. To determine conformance to 3.4.2.1, the compound shall show no

evidence of creep of 6.4 mm (0.25 in) or more on clean test panels. Two clean test panels made

of cold rolled steel of commercial quality and a minimum of 6.4 mm (0.25 in) thick shall be

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business