MIL-PRF-907F

4.3.2 Examination of filled containers. A sample of filled containers selected from each lot in accordance

with MIL-STD-1916 as specified in the contract or order shall be examined to verify compliance with all

stipulations of this specification regarding fill, closure, marking and other requirements not involving tests.

Containers shall be examined for defects of the container and the closure, for evidence of leakage, and for

unacceptable markings; each sample filled container shall also be weighed to determine the amount of the contents.

Any container in the sample having one or more defects, or under required fill shall cause rejection of the container

and if the number of defective containers in any sample exceeds the acceptable number for the appropriate sampling

plan as specified in the contract or order, this shall cause rejection of the lot represented by the sample.

4.3.2.1 Examination of compound material. Portions of the compound material shall be taken from top,

bottom and intermediate parts of the sample of containers and examined visually to determine that there is no

apparent difference in appearance or consistency. The material shall be homogeneous and show a smooth greasy

consistency without lumps, crusts or granular particles. It shall not have an odor of rancidity or perfume.

4.3.3 Sample material for testing. From each lot, a 5-pound container shall be selected, sealed and marked.

The 5-pound sample specimen shall be retained by the manufacturer or contractor for verification testing, if

required, at a later date.

4.3.4 Sampling for production check tests. Unless otherwise specified (see 6.2), from the first lot produced

on a contract or order and thereafter at such intervals as may be considered necessary by the command or agency

concerned to verify the consistency of production quality, one 2-pound sample and two 1-pound samples of

compound shall be forwarded to a laboratory acceptable to the command or agency concerned. These samples shall

meet the requirements of 3.6 and any other tests deemed necessary by the command or agency concerned to

determine conformance of the product.

4.4 Tests.

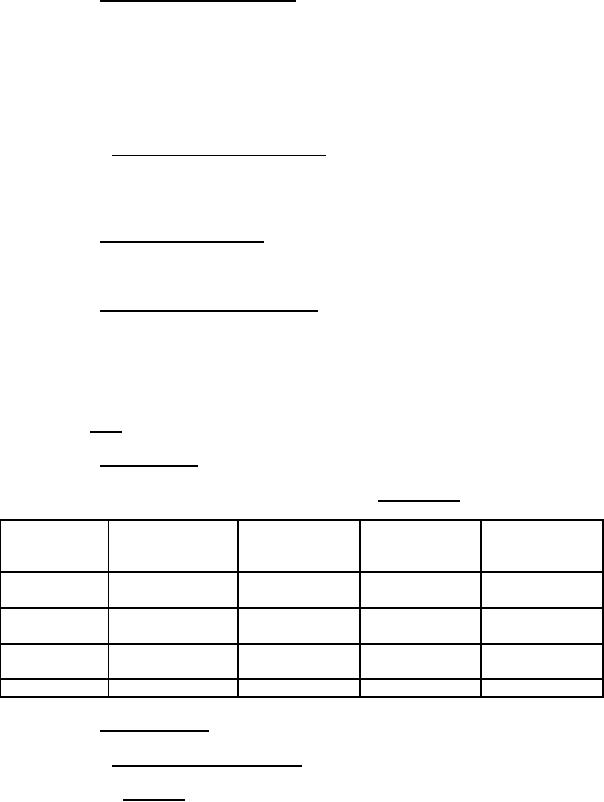

4.4.1 Test procedures. The following tests shall be performed in accordance with Table I.

TABLE I. Test methods.

Test

Applicable FED-

Test paragraph

Acceptance

Required for

STD-791 test

criteria

qualification

method

Corrosion on

5309

-----

3.3

X

copper

Oil separation

321

-----

3.6

X

(150°F)

Storage

3467

4.4.3

3.7

X

stability

Performance

4.4.2

3.8

X

4.4.2 Performance tests.

4.4.2.1 Torque, galling and seizing test.

4.4.2.1.1 Apparatus. The test apparatus shall consist of the following: A fixture made of carbon steel,

using material in accordance with ASTM A 515, grade 70, 13 by 3 inches by approximately 1-1/2 inches thick for

the end blocks which have 5 equally spaced holes, 13/16 inch in diameter, with surface finish of 250 roughness

height rating (RHR), to allow for insertion of ¾ inch 10 UNC studs (see Figure 1). The top and bottom faces of the

steel end blocks shall have a surface finish of 250 RHR and be parallel within ± 0.002. Five unused coarse thread

studs, in accordance with grade B16 of MIL-DTL-1222, ASTM A 193 or equal, cut from the same length of a

continuously threaded stud stock and ten unused nuts, in accordance with grade 4 of MIL-DTL-1222, ASTM A 194

or equal, shall be used for this test. Each stud shall be 12.000 ± 0.125 inches long and shall have end surfaces which

are perpendicular to the axis of the stud to a degree which shall allow stud length measurements of the required

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business