MIL-DTL-82633A (OS)

3.1.3 Workmanship. The individual components shall contain no volatiles or toluene diisocyanate

ingredient and shall be products of high quality, suitable for the purpose intended, and so manufactured as

to meet all requirements specified herein. Both components furnished under this specification shall be

uniform in quality and consistency after stirring and free of agglomerates or other contaminants. The

cured compound shall be free of low or high density areas and shall present an appearance of smooth

homogeneity.

3.1.4 Storage (shelf) life. The cured compound (see 6.4.1) shall meet all requirements of this

specification when produced from components that have been stored in unopened original containers no

longer than 8 months at ambient temperature.

3.2 Product characteristics.

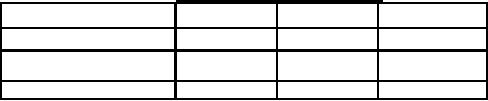

3.2.1 Physical properties of components. The components shall have the physical properties

specified in Table I.

TABLE I. Component physical properties.

Property

Component A

Component B

Test procedure

Specific gravity

0.91 ± 0.03

0.96 ± 0.03

4.4.1

1

Viscosity, cp (at 75 ± 5 ºF)

7,200 max.

12,000 max.

4.4.2

Flash point, ºF

500 min.

400 min.

4.4.3

1

Not to exceed 25,000 cp after 8 months of storage.

3.2.2 Exothermic temperature. The peak exothermic temperature of the reacting polymeric

compound shall not exceed 100 degrees Fahrenheit (°F) when tested in accordance with 4.4.4.

3.2.3 Gel time. The gelation (reaction) time of the reacting components shall be 6 ± 1 ½ minutes

when tested in accordance with 4.4.5.

3.2.4 Slump test. The gelled compound (see 6.4.2) shall not slump beyond the edge of the test

container when tested in accordance with 4.4.6.

3.2.5 Alkalinity. The cured compound shall have a pH value of 7.0 or less when tested in

accordance with 4.4.7.

3.2.6 Acidity. The cured compound shall have less than 0.01 percent acidity when tested in

accordance with 4.4.8.

3.2.7 Stability. The cured compound shall show no evidence of oil or other materials leaching out

when tested in accordance with 4.4.9.

3.3 Performance requirements.

3.3.1 Resistance to cold temperature. A disc of the cured compound shall not crack, chip, or show

deterioration when tested in accordance with 4.4.10.

3.3.2 Compression set. The cured compound shall have a compression set no greater than 50

percent when conditioned at 160 ºF and no greater than 2 percent when conditioned at -65 ºF and tested in

accordance with 4.4.11.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business