MIL-PRF-24176C

2.4 Order of precedence. In the event of a conflict between the text of this document and the references

cited herein, the text of this document takes precedence. Nothing in this document, however, supersedes

applicable laws and regulations unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 Qualification. The cement furnished under this specification shall be products that are authorized by

the qualifying activity for listing on the applicable qualified products list before contract award (see 4.1 and 6.4).

3.1.1 Requalification in case of reformulation. Any changes in the formulation of the product submitted

for qualification testing shall be cause for requalification of the product (see 4.2).

3.2 Cement. The cement shall be a two -component (component A-resin and component B-curing agent),

chemically reactive, epoxy cement, with suitable additives to produce a material in conformance with the

requirements specified herein. The use of any ozone depleting substance (ODS) in the composition of the cement

under this specification directly or referenced in any test method is hereto prohibited. Envi ronmentally safe and

non-ODS alternative solvents may be substituted for any previously specified ODS such as trichoroethylene (see

6.2). The use of asbestos or asbestos containing ingredients in the cement is prohibited.

3.3 Manufacture. Ingredients for each component shall be processed and mixed to produce a product

which is uniform, free from dirt and grit, and in full conformance with the requirements of this specification.

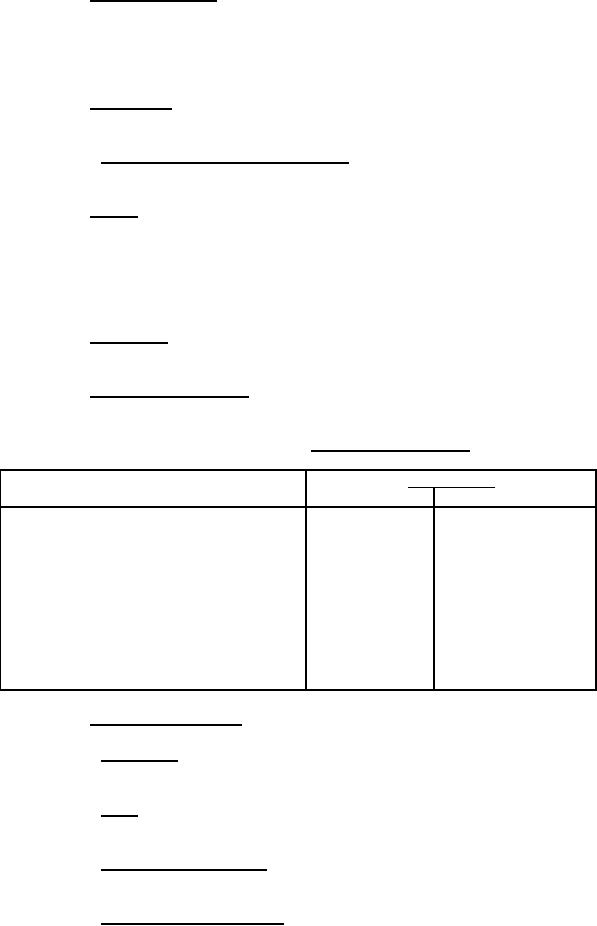

3.4 Quantitative requirements. The cement shall conform to the quantitative requirements shown in

Table I, and as herein specified.

TABLE I. Quantitative requirements.

Requirements

Characteristic

Minimum

Maximum

Hardness of cured epoxy cement, Type D units

55

---

Pot life, minutes

21°C ± 1°C (70°F ± 2°F)

15

180

32°C ± 1°C (90°F ± 2°F)

10

120

Curing time, hours

---

24

Compressive strength, pascal (lb/in2)

3.9 x 107

---

(5500)

Shrinkage, percent

---

0.25

3.5 Qualitative requirements. The cement shall conform to the qualitative requirements specified herein.

3.5.1 Consistency. The two components of the cement shall be of smooth, uniform consistency and

sufficiently viscous to allow ready mixing at temperatures between 21°C and 32°C (70°F and 90°F).

3.5.2 Color. The two components of the cement shall be of dissimilar colors and the finished cement

shall be a distinctive color different from either component when tested as specified in 4.5.3.

3.5.3 Application characteristics. The cement shall be trowelable and shall produce a smooth surface

when tested as specified in 4.5.5.

3.5.4 Resistance to vertical sagging. The cement shall not sag when tested as specified in 4.5.6.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business