MIL-PRF-24176C

end of the channel during a 24-hour period shall be noted and recorded. Sagging below lower end of the channel

shall constitute non-compliance with 3.5.4.

4.5.7 Curing time. The cemented channel test specimen utilized in 4.5.6 shall be used to determine the

curing time of the cement. Upon completion of the 24-hour vertical sag test, the cemented area of the channel

shall be sanded immediately with No. 60 aluminum oxide cloth and any gumming or roll-up of the cement on the

abrasive cloth shall be indicative of incomplete curing or hardening and shall be cause for rejection.

4.5.8 Adhesion and resistance to impact of cement bonded to metal.

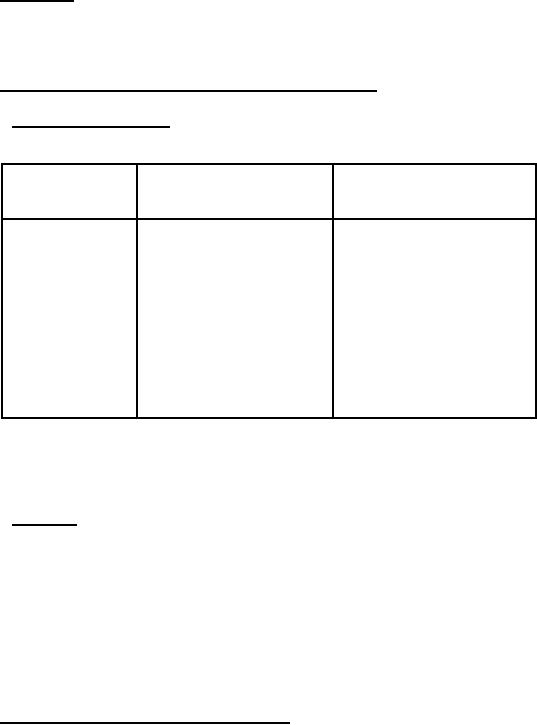

4.5.8.1 Preparation of specimens. Metal plates of the following compositions and dimensions shall be

prepared:

Dimensions,

Number of

Millimeters

plates

(inches)

Composition

4

150 by 150 by 6

Carbon steel (ASTM A 109)

(6 by 6 by 1/8)

4

150 by 150 by 6

Aluminum alloy

(6 by 6 by 1/8)

(ASTM B209) alloy 5456

6

3 by 75 diameter

Copper Alloy

(1/8 by 3 diameter)

(ASTM B 584) C 92300

All metal plate surfaces to be utilized for test purposes shall be cleaned and finished with a No. 60 aluminum oxide

cloth. Specimens shall be prepared by applying a 1.5 mm (1/16 inch) layer of freshly-prepared cement to the

finished surface of the test plates.

4.5.8.2 Procedure. One half the number of specimens prepared with each type alloy shall be cured for 7

days with the remaining specimens cured for 3 months. At the end of the 7-day and 3-month curing periods, the

cemented surfaces of the specimens shall be subjected to an impact of a 0.9-kilogram (kg) (2-pound) steel ball

dropped from a height of 0.6 meter (m) (2 feet). Four impacts, each approximately 64 mm (2-1/2 inches) from

each corner along the diagonal, shall be made upon each aluminum and steel alloy specimen. The copper alloy

specimens shall be subjected to two impacts, 25 mm (1 inch) apart along the diameter. Detachment of the cement

from the plate or poor adhesion beyond a radius of 6 mm (1/4 inch) from the center of impact shall constitute

failure. Each impact area shall be gouged with a 6 mm (1/4 inch) chisel to create a 1 inch long groove that extends

into the base metal to verify adhesion of the cement. Visible separation at the interface of the cement and base

metal in the walls of the groove shall constitute failure.

4.5.9 Compatibility of cement with primers and paint. Metal plates shall be prepared as specified in

4.5.8.1, except that primer conforming to MIL-DTL-24441, Type IV shall be applied to the finished surfaces to

produce a dry film thickness of 65 to 90 µm (2.5 to 3.5 mils). The primer shall be allowed to dry for 24 hours and

then shall be covered with a 1.6 mm (1/16-inch) layer of freshly-prepared cement. Upon curing for a period of 48

hours, and without sanding, one half the number of specimens shall be over-coated with paint system "A" and the

remaining specimens with paint system "B", defined as follows:

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business