MIL-C-47244A(MI)

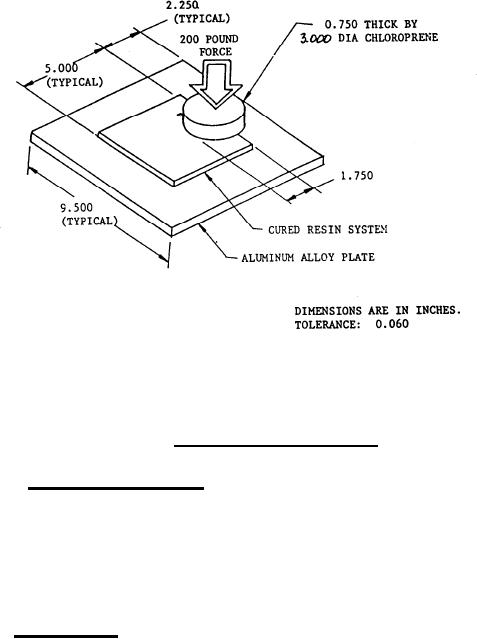

FIGURE 2. Tread resistance test setup.

4.6.11.2 Resistance to test fluid. The remaining half of each of the test panels

shall be immersed in hydrocarbon test fluid conforming to TT-S-735, Type I, for not

less' than 25 minutes. Upon removal, the test panel shall be allowed to air-dry for not

less than 30 minutes. The test specified in 4.6.11.1 shall be repeated except that the

flame shall be applied to the portion of the resin system that had been immersed in the

test fluid.

4.6.12 Blast erosion. The blast erosion test shall be performed using a

combustion chamber capable of generating exhaust products having the composition

and characteristics specified in 3.3.12. The nozzle of the combustion chamber shall

have an exit-to-throat area ratio of 5.5 ± 0.1. A test panel having a known resin system

thickness shall be placed in a temperature chamber controlled at 94° ± 3°C and allowed

to remain at this temperature until stabilized. Within 5 minutes after removal from the

temperature chamber, the test panel shall be exposed to the exhaust emanating from

the combustion chamber for not less than 90 milliseconds. During exposure, the test

panel shall be securely positioned, so that the surface of the resin system is

downstream from and normal (± 5 degrees) to the flow from the combustion chamber

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business