MIL-DTL-3301D

d. There has been a change in the source of supplies for the materials used in the manufacture of the

asphaltic compound.

.

3.2 Materials. The materials used in the manufacture of the asphaltic compound shall be of acceptable

quality, suitable for the purpose intended, and shall be such as to produce a compound which shall be

easily heat liquefiable but which does not flow at temperatures below the softening point. The compound

shall contain no volatile solvents.

3.3 Heat resistance. When tested as specified in 4.4.2, a dried film of the compound on a metal panel

shall not sag or flow when heated by immersion in a glycerin bath maintained at 109 ± l ºC (228 ± 2 ºF)

for 1 hour.

3.4 Acid resistance. When tested as specified in 4.4.3, a dried film of the compound on a metal panel

shall withstand the action of picric, sulfuric, nitric, and hydrochloric acids for 6 hours without

disintegration, browning, or dulling. There shall be no etching of the metal underneath the compound.

3.5 Water resistance. When tested as specified in 4.4.4, a dried film of the compound on a metal panel

shall withstand immersion in distilled water for 18 hours without blistering, whitening, and not more than

a slight dulling.

3.6 Flexibility. A dried film of the compound on a metal panel shall show no chipping, scaling, or

cracking when tested as specified in 4.4.5.

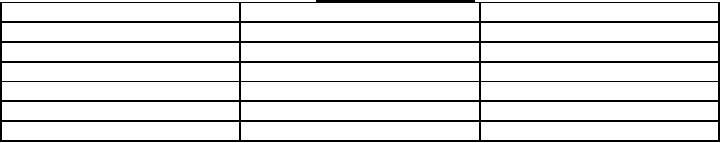

3.7 Chemical requirements. The asphaltic compound shall conform to the chemical requirements of

Table I when tested as specified therein.

TABLE I. Chemical requirements.

Requirement

Percent maximum

Test paragraph

Acidity, as H2S04

0.01

4.4.6

Alkalinity, as NaOH

0.01

4.4.6

Insoluble matter in toluene

1.00

4.4.7

1.00*

Ash

4.4.8

0.10*

Manganese

4.4.9

0.04*

Lead

4.4.10

*

Quality conformance tests for manganese and lead shall not be required when the ash content is less than 0.04 percent.

3.8 Softening point. The softening point of the asphaltic compound shall be not less than 113 ºC (235 ºF)

when tested as specified in 4.4.11.

3.9 Penetration. The asphaltic compound shall conform to the following penetration values when tested

as specified in 4.4.12:

200gm/60 sec. /0 ºC (32 ºF)

15 min.

100gm/ 5 sec. /25 ºC (77 ºF)

25 min.

50gm/ 5 sec. /46 ºC (115 ºF)

80 max..

3.10 Viscosity. The viscosity of the asphaltic compound shall be not more than 700 centipoises at 149 ºC

(300 ºF) when tested as specified in 4.4.13.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business