MIL-PRF-81733D

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified

as follows:

a. Qualification inspection (see 4.3).

b. Conformance inspection (see 4.4).

4.2 Inspection conditions. Unless otherwise specified, all inspections shall be performed in

accordance with the test conditions specified in the applicable test method or test paragraph in

this specification.

4.3 Qualification inspection. Qualification inspection shall consist of all the tests specified in

table V.

4.3.1 Samples. Qualification test samples shall consist of 5 quarts of Type I, 8 quarts of

Type II, 8 pints of Type III, and 5 quarts of Type IV base compound, together with sufficient

curing agent for each type, of the class for which qualification is desired. The samples shall be

furnished in units of issue as specified in 3.2.2.

4.4 Conformance inspection. Materials acquired by the Government under this specification

shall be source inspected in accordance with 4.4.2 to ensure the material meets the conformance

inspection prior to shipment from the manufacturer's plant. Conformance test samples shall be

packaged and mixed in, as near as practical, the units of issue as specified in 3.2.2.

4.4.1 Sampling. A 1-quart container or a sufficient number of containers to allow

preparation of test specimens shall be randomly selected from each lot and tested as specified in

4.4.2.

4.4.2 Examination. The sample selected in 4.4.1 shall be tested to the requirements specified

in table VI. Nonconformance with any specified requirement shall be cause for rejection of the lot

represented by the sample.

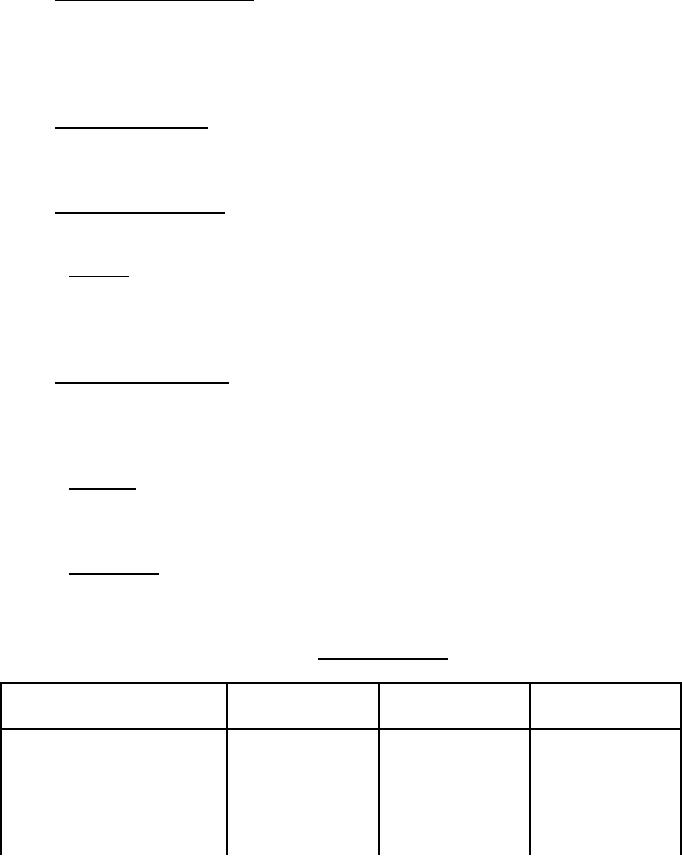

TABLE V. Qualification tests.

Test

Requirement

Test

Characteristic

Method

Paragraph

Paragraph

Appearance

3.3.1.1

4.8.1

Color

3.3.1.2

4.8.1

Nonvolatile content

3.3.1.3

4.8.2

Flow

3.3.1.4

4.8.3

Application life

3.3.1.5

4.8.4

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business