MIL-PRF-81733D

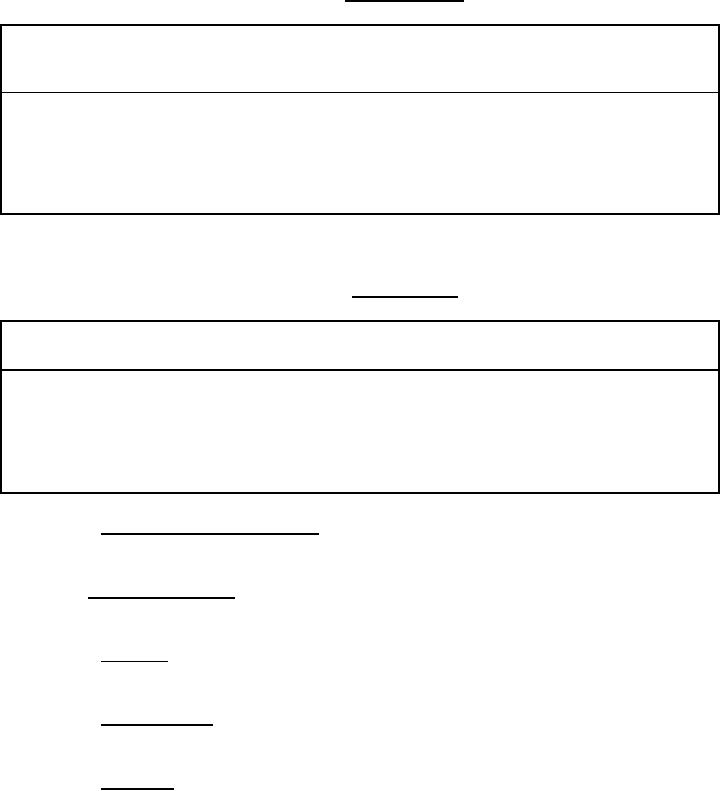

TABLE III. Application time.

Minimum

Minimum

Minimum

Minimum

Time,

Time,

Time,

Time,

Type I

hours

Type II

hours

Type III

hours

Type IV

hours

-1/61

-42

1/6

4

-1/42

1/4

-1/4

1/4

-1

1

-12

12

-1/2

1/2

-1/2

1/2

-24

24

-2

2

-2

2

-40

40

-4

4

-48

48

1

Class 1 only.

2

Class 2 only.

TABLE IV. Tack-free time.

Type

Time, hours

Type

Time, hours

Type

Time, hours

I

Class 1

Class 2

II

Class 1

Class 2

III

Class 1

Class 2

-1/6

4

-1/4

-

4

-1/4

8

1

-1

8

8

-1/2

16

8

-1/2

16

2

-2

24

16

-2

24

12

-4

24

3.3.1.7 Assembly time (Type IV only). The sealant shall squeeze out to a thickness no

greater than 0.005 inch at the bolts when tested as specified in 4.8.6.

3.3.2 Properties after cure. Unless otherwise specified, all test specimens shall be cured as

specified in 4.7.

3.3.2.1 Hardness. When tested as specified in 4.8.7, the Shore A-2 hardness of the cured

sealing compound shall be not less than 35 for Types I, II, and III or 30 for Type IV.

3.3.2.2 Specific gravity. When tested as specified in 4.8.8, the specific gravity of the cured

sealing compound shall be not greater than 1.65 for Class 1 or 1.50 for Class 2.

3.3.2.3 Corrosion. When tested as specified in 4.8.9, the cured sealing compound shall not

in itself induce corrosion and shall protect the substrate metal. There shall be no visible evidence

of corrosion at the metal-sealant interface.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business