MIL-PRF-81733D

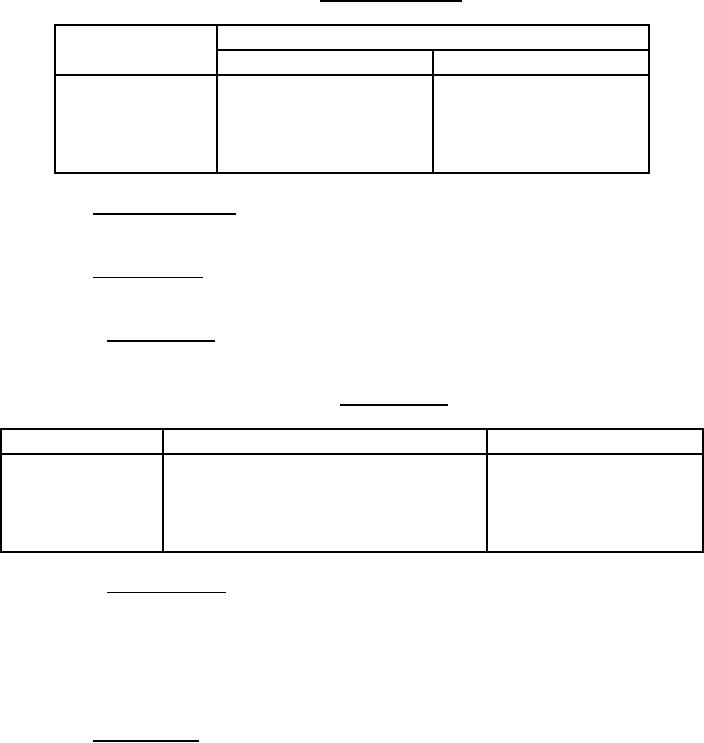

TABLE I. Nonvolatile content.

Nonvolatile Content, minimum percent by weight

Type

Class 1

Class 2

I

84

84

II

92

92

III

65

65

IV

90

95

3.3.1.4 Flow (Type II only). When tested as specified in 4.8.3, the flow measurement of the

sealing compound shall be not less than 0.10 inch and not greater than 0.75 inch.

3.3.1.5 Application life. Application life shall consist of the initial viscosity of the base

compound and an application time measurement of the mixed compound (see 4.8.4).

3.3.1.5.1 Initial viscosity. When tested as specified in 4.8.4.1, the initial viscosity of the base

compound shall be as specified in table II.

TABLE II. Initial viscosity.

Type

Application

Viscosity, poises

I

Brush or dip

100500

II

Extrusion or injection, gun or spatula

6,00016,000

III

Spray

50150

IV

Faying surface injection, gun or spatula

1,0004,000

3.3.1.5.2 Application time. When tested as specified in 4.8.4.2, the application time of the

compound that is prepared according to the manufacturer's instructions shall be as specified in

table III. The end of the application time shall be considered to be not greater than 2,500 poises

for Type I, not less than 15 grams per minute for Type II, not greater than 300 poises for Type

III, and not less than 30 grams per minute for Type IV, Class 1 or 50 grams per minute for Type

IV Class 2.

3.3.1.6 Tack-free time. When tested as specified in 4.8.5, the sealing compound shall cure

to a tack-free condition within the time specified in table IV.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business