MIL-DTL-85054D(AS)

4.6. Test methods. The tests of this specification shall be conducted in accordance with

table III.

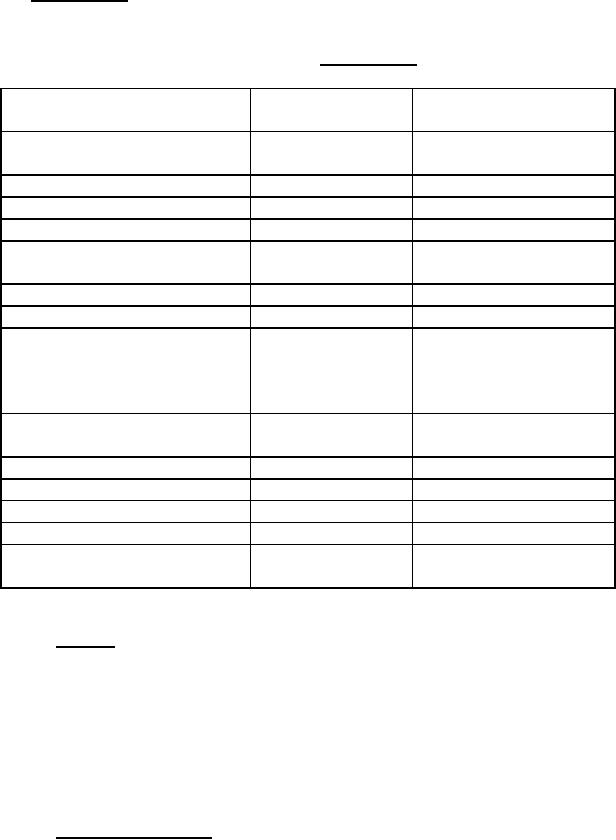

TABLE III. Test methods.

Test

Requirement

Test Method or

Paragraph

Test Paragraph

VOC content

3.2.1.1 and 3.2.1.2

40 CFR 60 Appendix A,

Method 24

Appearance

3.3

Visual

Dryness

3.4

4.6.1

Neutral salt spray

3.4

4.6.2

Synthetic sea water

3.4

4.6.3

displacement

Sprayability

3.4

4.6.4

Storage stability

3.4

4.6.5

Self-pressurized container tests:

Leakage

3.5.1

4.6.6.1

Fill

3.5.2

4.6.6.2

Performance

3.5.3

4.6.6.3

Coating Transparency and

3.4

4.6.7

Discernability

Coating Removability

3.4

4.6.8

Drying Time

3.4

4.6.9

Low Temperature Adhesion

3.4

4.6.10

High Temperature Adhesion

3.4

4.6.11

Compatibility with polyimide

3.4

4.6.12

and PTFE wiring insulation

4.6.1 Dryness. Three test disks prepared as specified in 4.4.1 and 4.4.2 shall be coated as

specified in 4.4.3 using compound conditioned as specified in 4.6.2.1 and allowed to hang in a

vertical position for three hours. The disks shall then be weighed and completely immersed

vertically in talcum powder and withdrawn immediately. The disks shall then be reweighed to the

nearest 0.0001 gram. The average change in weight shall be recorded. This procedure shall be

repeated with uncoated test panels. The uncoated test panels shall be used as controls. The

average weight increase of the coated panels as compared with the weight increase of the

uncoated panels shall be the measure of dryness.

4.6.2 Neutral salt spray test. Test panels prepared and coated as specified in 4.5

shall be subjected to ASTM B117 salt spray exposure. Incline three specimens at 6 degrees in a

rack. After 28 days, clean test panels in solvent conforming to MIL-PRF-680, and examine for

any visible corrosion.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business