MIL-DTL-85054D(AS)

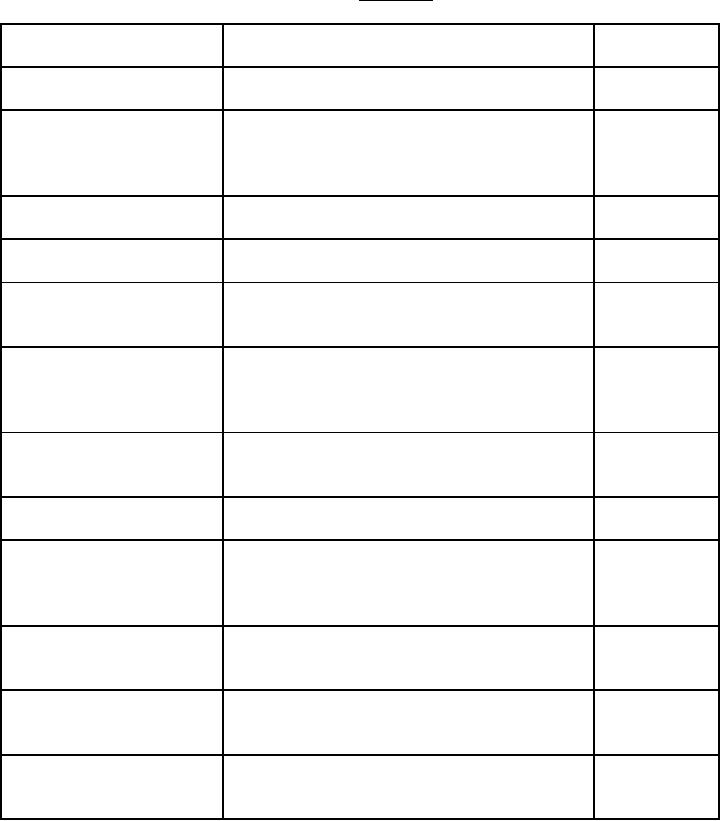

TABLE I. Properties.

TEST

PROPERTY

REQUIREMENT

PARAGRAPH

Dryness

0.0100 gram (max)

4.6.1

Neutral salt spray corrosion

No visible corrosion on 2024-T3 aluminum after

4.6.2

resistance (in accordance

28 days

with ASTM B117)

Synthetic sea water

No visible corrosion

4.6.3

displacement

Sprayability

Uniform spray pattern

4.6.4

Storage stability

Shall meet all requirements herein

4.6.5

(except storage stability) after one year storage at

room temperature

Coating Discernability

Demarcation line between coated and uncoated

4.6.7

part of panel shall be clearly discernible under

visible light.

Coating Transparency

Detection by the unaided eye of underlying

4.6. 7

simulated corrosion spots.

Removability

Completely removable with MIL-PRF-680

4.6.8

Drying Time

Coated panel shall become

4.6.9

completely dry to touch after 24 hours drying,

but dry for handling in 3 hours.

Lowtemperature adhesion

Flaking less than 0.05 inch when conducted at

4.6.10

30 ± 5 °F

High temperature adhesion

Max. of 0.05 inch flow at 200 °F with no

4.6.11

discoloration or loss of flexibility

Compatibility with

No cracking or degradation of insulation

4.6.12

Polyimide Wiring Insulation following prolonged exposure; No dielectric

leakage

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business