MIL-PRF-23586F

value from 4.7.5. After heat aging, the hardness shall not decrease by more than 7 points from the

deep section cure hardness.

3.3.2.4 Storage life. After being stored as specified in 4.7.18, the viscosity of the base

compound shall not exceed by more than 30 percent the as-received viscosity, and cured specimens

made from the stored compound shall exhibit a hardness within ±5 points of the as-received

hardness.

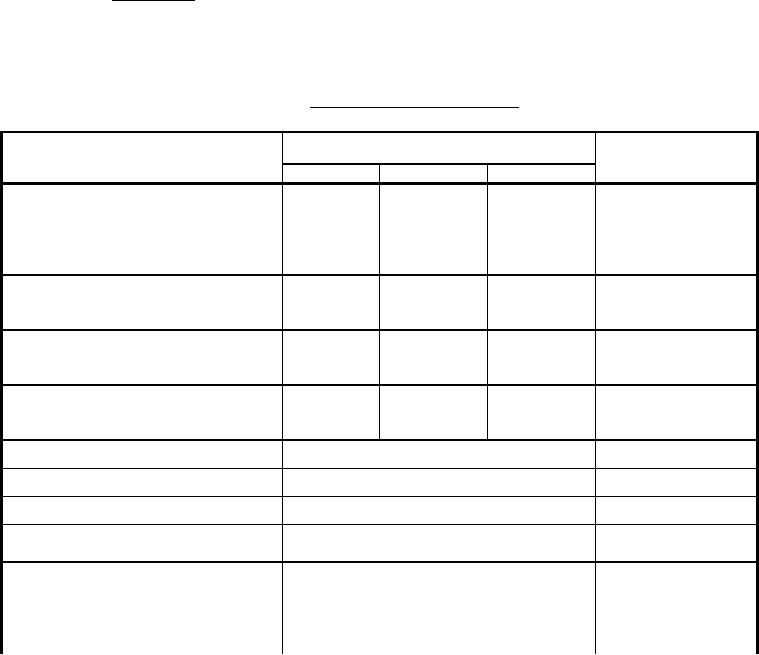

TABLE I. Physical properties after cure.

Characteristics

Requirements by type

Test paragraph

I

II

III

Hardness, points, minimum:

45

40

Class 1

45

30

35

Class 2

45

4.7.5

45

40

Class 3

45

50

35

Class 4

--

Tensile strength, psi, minimum

325

250

Classes 1,2, and 3

400

4.7.6

600

150

Class 4

---

Elongation, percent (%), minimum

100

100

Classes 1,2, and 3

100

4.7.6

150

Class 4

70

---

Linear shrinkage, %, maximum

4.7.7

Classes 1,2, and 3

1.0

1.0

1.0

Class 4

2.5

2.0

---

Specific gravity, maximum

1.50

4.7.8

Brittle point, °F, maximum

-90°

4.7.9

Adhesion, pounds, minimum

4

4.7.10

Hydrolytic stability: Hardness after

30

4.7.12

exposure, points, minimum

Water immersion 72 hours at 60°C,

change in:

±2

4.7.13

Weight, %, maximum

±3

Volume, %, maximum

Hardness, points, maximum

10

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business