MIL-PRF-23586F

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as

follows:

a. Qualification inspection (see 4.2).

b. Conformance inspection (see 4.3).

4.2 Qualification inspection. The qualification inspection shall consists of all the tests

specified in table III.

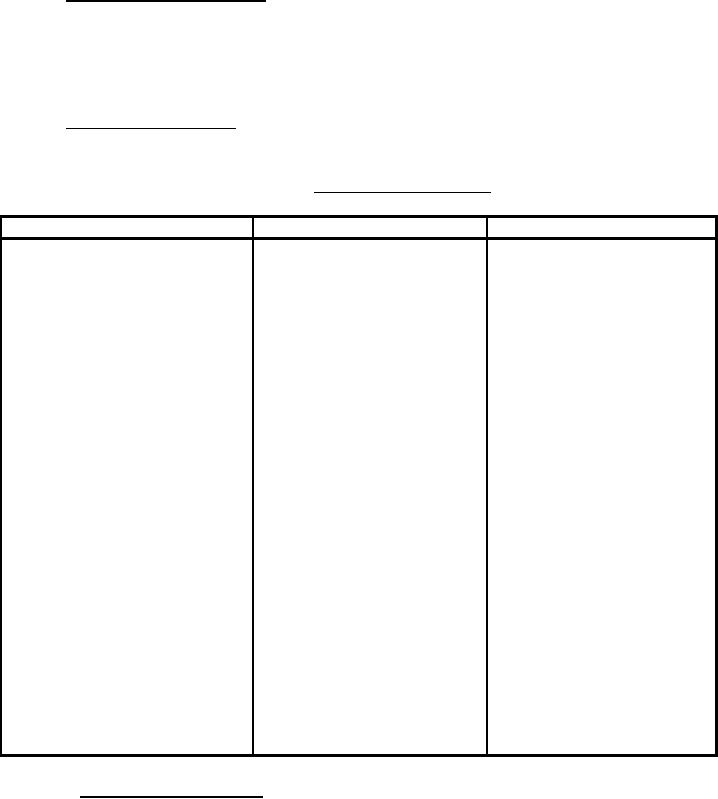

TABLE III. Qualification inspections.

Property

Requirement

Test Method

Appearance

3.3.1.1

4.7.1

Nonvolatile content

3.3.1.2

4.7.2

Viscosity base compound

3.3.1.3

4.7.3

Application properties

3.3.1.4

4.7.4

Hardness

Table I

4.7.5

Tensile strength

Table I

4.7.6

Elongation

Table I

4.7.6

Linear shrinkage

Table I

4.7.7

Specific gravity

Table I

4.7.8

Brittle point

Table I

4.7.9

Adhesion

Table I

4.7.10

Repairability

Table I

4.7.11

Hydrolytic stability

Table I

4.7.12

Water immersion

Table I

4.7.13

Oil immersion

Table I

4.7.14

High-temperature aging

Table I

4.7.15

Corrosion

3.3.2.2

4.7.16

Reversion resistance

3.3.2.3

4.7.17

Storage life

3.3.2.4

4.7.18

Unit of issue

3.4

Visual

Instructions for use

3.5

Visual

Dielectric strength

Table II

4.7.19

Volume and surface resistivity

Table II

4.7.20

Dielectric constant

Table II

4.7.21

Dissipation factor

Table II

4.7.21

Arc resistance

Table II

4.7.22

4.2.1 Qualification test samples. Qualification test samples shall consist of 12 one pound units

of the base compound, together with the necessary curing agent and primer (when required), of the

type, class and grade for which qualification is desired. The compound, curing agent and primer

shall be furnished in containers of the type to be used in filling contract orders. Samples shall be

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business