MIL-PRF-23586F

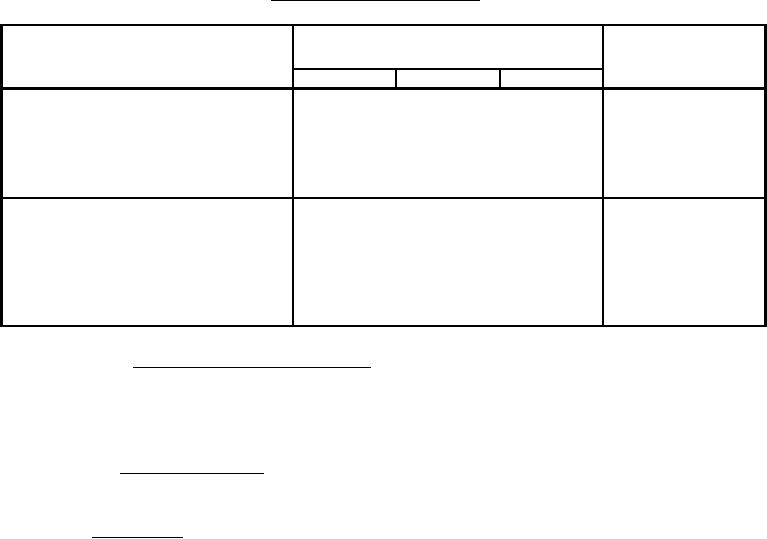

TABLE I. Physical properties after cure. - Continued.

Requirements by type

Characteristics

Test paragraph

I

II

III

Oil immersion 72 hours at 100°C, change in:

+5

Weight, %, maximum

+10

Volume, %, maximum

4.7.14

-10

Hardness, points, maximum

-25

Tensile strength, %, maximum

-25

Elongation, % from original, % maximum

Heat aging 72 hours at 204°C:

4

Adhesion, pounds, minimum

Change in:

±10

4.7.15

Hardness, points, maximum

Tensile strength, %, maximum

-25

Elongation, % from original,

-25

%, maximum

3.3.2.4.1 Shelf life extension (for field use). The field storage life of these compounds may be

extended an additional 3 months providing the requirements specified in 3.3.2.4 are met. The

method of examination shall be as specified in 4.7.18.1. Material may be tested again after 3 more

months storage. If acceptable, extend the storage period an additional 3 months.

3.3.2.5 Electrical properties. The electrical properties of the cured sealing compound shall

conform to the requirements in table II.

3.4 Unit of issue. In order to interface with existing equipment and meet the required storage

characteristics, the sealing compound unit of issue shall be in kits as follows:

a. 1 pint and 1 gallon kits - Base compound filled to 75 percent by volume in multiple

friction top 1 pint or 1 gallon metal containers with the appropriate amount of curing

agent in smooth, vertical, glass lined or plastic lined jars with screw cap (to facilitate

removal of the curing agent).

b. 2½ ounce and 6 ounce sectional type (see 6.7) kits - The total content (base compound

and curing agent) shall be 2 fluid ounces in the 2½ and 3½ fluid ounces in the 6 ounce

sectional type container. The volume tolerance shall be ±1/8 fluid ounce.

c. 5 gallon kit - The base compound shall be supplied in 5 gallon metal containers with

sealed crimped lids. Appropriate amounts of curing agent shall be in multiple friction top

metal containers. Appropriate amounts of the supplier recommended primer shall be

furnished in containers compatible with the primer. The ratio of the quantity contained in

the base compound container to the quantity contained in the attached curing agent

container shall be the same as the recommended mixing ratio of the base compound and

curing agent.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business