MIL-PRF-8516G

3.2.3 Toxicity. The sealing compound, when used for its intended purpose, shall have no

adverse effect on the health of personnel.

3.2.4 Shelf life. The shelf life of the sealing compound shall be not less than 9 months.

Sealing compound which has exceeded its shelf life may be retested to extend storage (see 6.5).

3.3 Performance characteristics.

3.3.1 Properties before cure.

3.3.1.1 Color. Unless otherwise specified in the contract or order, the base compound shall

be supplied in the manufactured color and shall contrast with the curing agent to facilitate mixing

(see 6.2). The material shall not be red in color.

3.3.1.2 Consistency during electrical connector sealing (potting) operations. The mixed

sealing compound shall be pourable at normal temperatures, but shall not flow through

connectors during electrical connector sealing (potting) operations (see 4.6.1.3).

3.3.1.3 Application life. When tested in accordance with 4.9.2.1, the mixed category A

sealing compound shall meet the requirements of initial viscosity (see 3.3.1.3.1) and application

time (see 3.3.1.3.2).

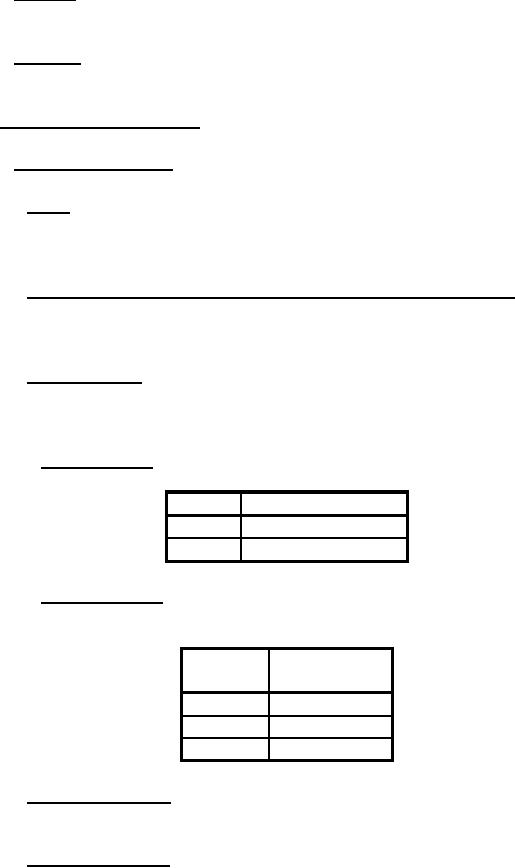

3.3.1.3.1 Initial viscosity. The initial viscosity of the mixed compound shall be:

Type

Initial viscosity

I

100 to 400 poises

II

401 to 1,200 poises

3.3.1.3.2 Application time. The application time (minimum time to reach 1,000 poises for

type I and 2,500 poises for type II) of the mixed compound shall be:

Class

Minimum

time

1

30 minutes

2

60 minutes

3

120 minutes

3.3.1.4 Nonvolatile content. When tested in accordance with 4.9.2.2, the nonvolatile

content of the mixed sealing compound shall be not less than 94 percent.

3.3.1.5 Accelerated storage. When tested in accordance with 4.9.2.11, the mixed compound

shall not deviate from the initial viscosity (see 3.3.1.3.1) by more than plus 35, minus 5 percent

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business