MIL-PRF-8516G

and shall meet the application time requirements (see 3.3.1.3.2), the set time requirements (see

table I), and cure A hardness requirements (see table I).

3.3.1.6 Long-term storage. When tested in accordance with 4.9.2.12, the mixed category A

sealing compound shall meet the requirements of application life (see 3.3.1.3) and cure A and B

hardness (see table I).

3.3.2 Properties after cure. Unless otherwise specified in the test method, all test specimens

shall be cured as specified in 4.7.

3.3.2.1 Nonelectric properties. The nonelectric properties of the cured sealing compound

shall be as specified in table I.

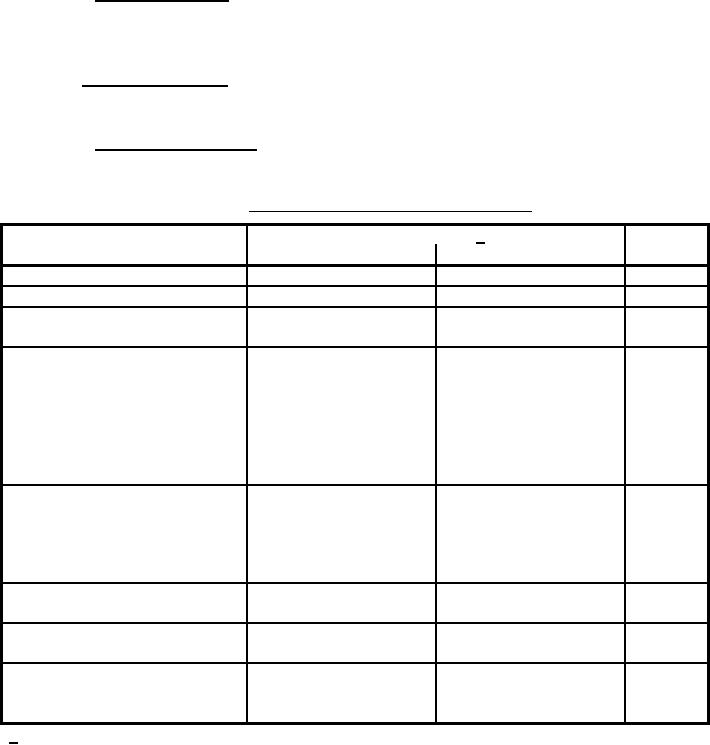

TABLE I. Nonelectric properties of cured compound.

Property

Requirement 1/

Test

Cure A (4.7.1)

Cure B (4.7.2)

paragraph

Set time

No sag or flow

No sag or flow

4.9.2.3

Shrinkage, percent, maximum

10

10

4.9.2.4

Hardness, Shore A-2 initial,

Type I - 20, minimum

Type I - 30 to 60

4.9.2.5

points

Type II - 25, minimum

Type II - 30 to 60

Adhesion, (piw), minimum

4.9.2.6

Aluminum alloy

2

15

Chromated cadmium plated steel

2

15

Diallyl phthalate plastic

15

Nylon plastic

2

15

Polytetrafluoroethylene (PTFE),

2

treated

Fluid resistance

4.9.2.7

Adhesion after immersion,

10

pounds, minimum

Change in hardness, points,

±10

maximum

Low temperature flexibility

No checking, cracking, or

4.9.2.8

separation from test panel

Corrosion

No greater corrosion than

4.9.2.9

control wire

Hydrolytic stability, physical

+15

4.9.2.10

Change in hardness after

5

exposure, points

1/ Unless otherwise specified, the given value is for all types and classes. "" indicates no

requirement.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business